Elecom Deft Pro Bearing Swap

This is a guide on how to swap the bearings in your Elecom Deft Pro trackball. The ruby ones that come from the factory aren’t great because they make small movements difficult due to sticking.

You should absolutely read this popular guide too from /u/KgOfHedgehogs. You should also watch this excellent video about doing the same process for the Elecom Huge. This guide is really just adapting that to the Deft Pro. Note: all the red lines are drawn with the trackball, so that’s why they look so horrible.

Thingies used:

- ZrO2 ceramic bearings

- toolkit to get the Torx T6 and phillips PZ00 bits needed

- masking tape, but any tape will be fine. Maybe even Blu-Tack

Summary

The ball bearings are in the trackball cup. This cup is made in two halves that are held together by 3 screws. You need to disassemble the device enough to be able to undo those screws and replace the bearings.

Brief steps

- remove screws

- lift thumb cluster out

- unclip trackball cup

- unscrew the laser PCB

- put tape over the balls

- unscrew the cup

- replace balls

- follow steps in reverse to assemble

Detailed steps

Remove the trackball

Same as usualy, flip it upside down and push through the hole on the bottom.

Remove the 7 screws on the bottom

These screws are Torx T6, which comes in the kit I linked above. They’re all the same, so you don’t have to worry about mixing them up. You’ll have to peel off the rubber pads to access most of them. The pads stick back on after, so you don’t have to buy new pads. For the one screw that’s under the label, just feel for it and punch through the sticker. You can place the screws on a piece of tape to stop them from getting lost if that helps you.

The linked imgur guide nicely shows all the screws.

You can see five of the screws here:

The screw under the left pad is inline with the centre of the battery, unpeel it

from the bottom:

The screw under the right pad is in the middle of that pad, so unpeel from

either end:

The screw under the label. Just feel for it and punch through. No need to remove

the label:

Remove the top cover of the trackball

With all the screws out, the top cover will lift off. Start by opening at the back of the device, it won’t take much effort to open. If it’s hard to open, make sure you’re removed 7 screws.

There are no wires going to the top cover of the device, so you can lift it without fear of tearing a connection out. The front of the cover is held by two tabs. You get the cover off by lifting and jiggling it.

Remove the thumb button cluster

There is a cable attached. You don’t have to undo it, but don’t rip it out.

This is just sitting there. It was held in by a screw, but you removed that so you can just lift it up. You have to remove it to make it easier to remove the trackball cup. There is a cable going to the thumb cluster. You do not have to unplug the cable, just be careful not to tear it out when you’re working.

Remove the trackball cup

There is a cable attached. You don’t have to undo it, but don’t rip it out.

The screws that hold the trackball cup together are removed from the bottom, so you have to remove the cup, which is what we’re doing in this step. It’s held down by three tab clip thingies.

I undid the left side clips first and once they were clear of the tabs, I only had to press a tiny amount on the right side to release it. I found it a bit tricky to get the front-left tab, and seeing as nobody else has complained about this, I probably did it the wrong way. I did try releasing the right side and lifting it, but it didn’t go. Perhaps I should’ve tried harder. For me, this was the most frustrating step. Make sure you don’t rip the cable out when you remove the cup.

The single tab on the right:

The two tabs on the left:

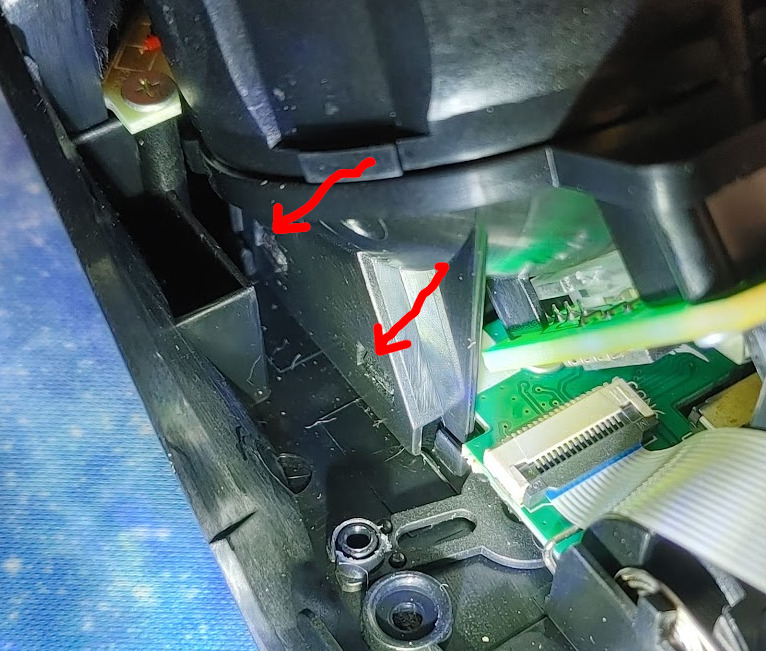

I ended up using one side of a pair of tweezers to hold the front-left tab tab

open, then it was easy to press the other clips with a screwdriver and pop the

cup off:

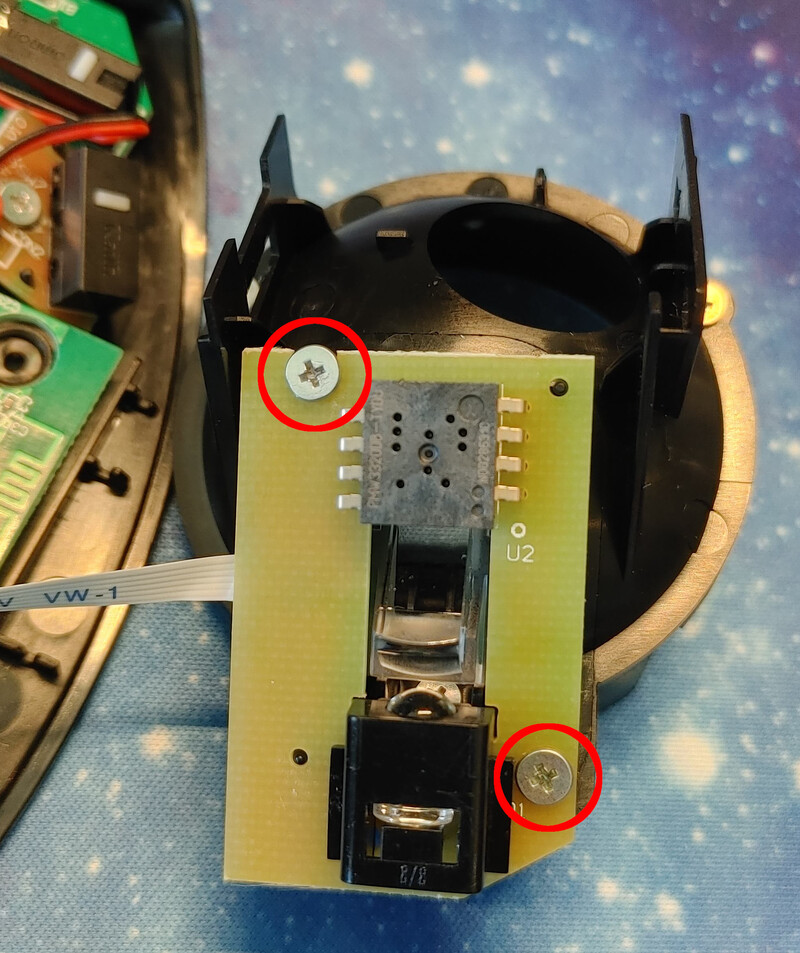

Unscrew the laser/sensor PCB

There is one screw for the cup under this PCB so we have to remove it. There are two screws on the PCB that I used a phillips PZ00 bit on. The plastic lens for the laser is just sandwiched in place so pay attention to which way it comes out.

Cup removed without disconnecting any cables:

Tape the bearings

Once you undo the two halves of the cup, the bearings will fall out. If you don’t control them, they’ll bounce like crazy and you’ll never see them again. To control them, tear off three pieces of tape and place one over each ball.

Separate the cup halves

There are three screws holding the trackball cup together. Undo them (I used the same phillips PZ00 bit). The halves have locating pins so you’ll have to gently pry them apart with something thin. Be careful that the balls stay stuck to the tape while doing this.

You don’t have to fully separate the halves, although you might find that easier. You only have to get them far enough apart that you can swap the balls out.

The three screws:

Swap the balls

This is what we’re here for. Get your new ball bearings and swap them in. Use pieces of tape to make them easier to handle. You can use another piece of tape to stop the spares from rolling around on the desk:

Screw the cup back together

As you do this, make sure

- you don’t get tape caught between the halves

- the balls stay in place

- you pay attention to the two small locating pins between the halves. There is only one correct way to assemble the halves.

Put everything back together

Just follow all the steps in reverse:

- screw the laser/sensor PCB back on, making sure the plastic lens is sandwiched between the PCB and cup

- clip the cup back on

- place the thumb cluster in place

- put the top cover back on, starting with the two clips at the front then closing the back

- put all 7 screws back in

- stick the pads back on

- if you have some alcohol spray, clean the ball bearings in case they have sticky residue from the tape

- put the ball back in